Encore Electric Provides Design-Assist Services for State-of-the-Art Facility

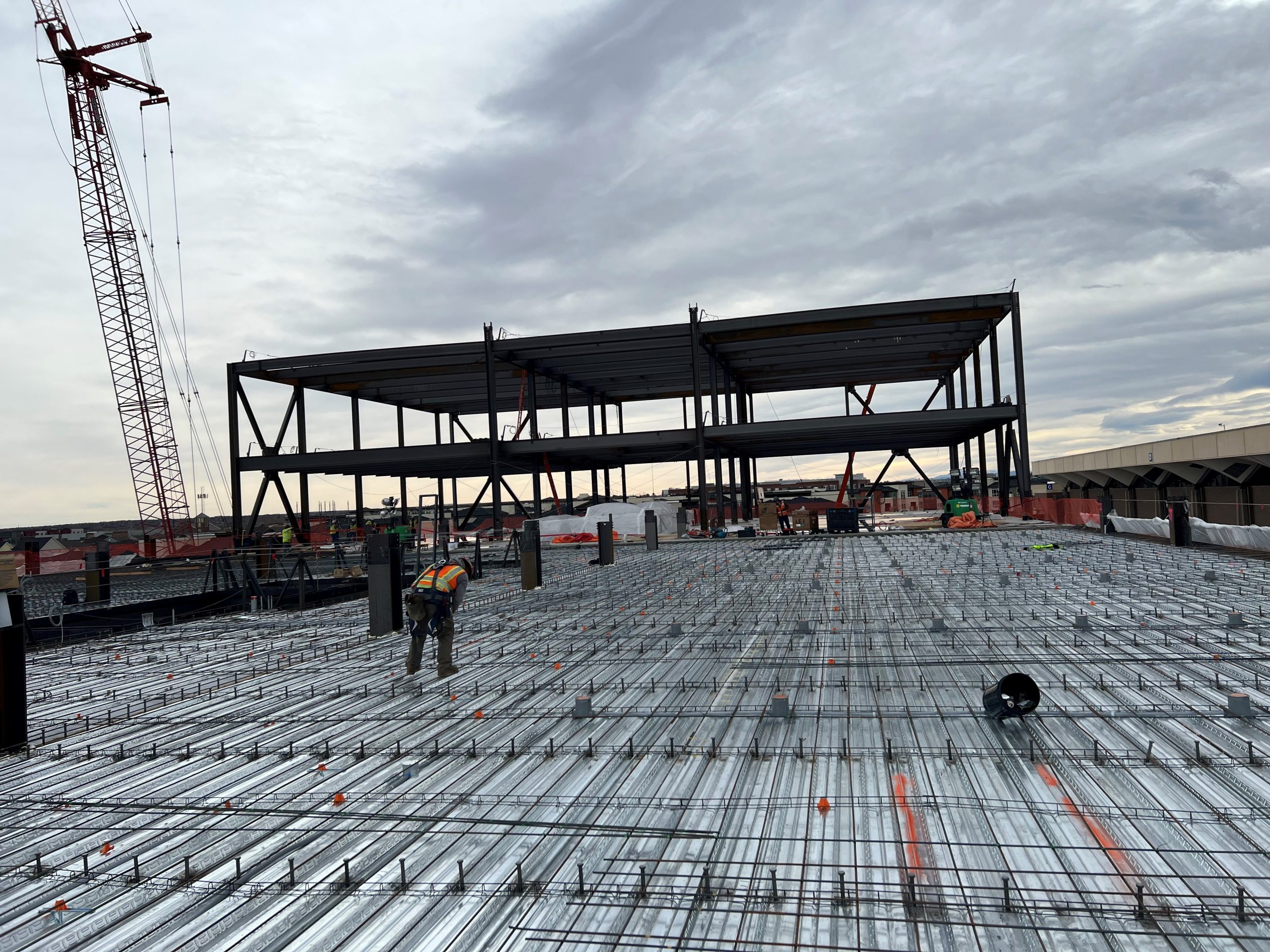

February 8, 2024 – Lakewood, CO – As one of the largest commercial airlines in the country, United Airlines trains thousands of pilots each year and recently set an ambitious goal to recruit and train another 10,000 pilots by 2030. To achieve this goal, a new cutting-edge 150,000 square feet of training space was added to the United Airlines Flight Training Center Campus. The facility operates 20 hours a day, 362 days a year, with shutdowns only for Thanksgiving, Christmas, and New Year’s Day. To provide design-assist services, Encore Electric was selected to partner with Turner Construction, United, and industry trade partners for the construction of the facility located in Denver, Colorado.

Encore Electric had a vital role in the construction of the new United Airlines Flight Training Center building, which is an expansion of their existing global training campus. In addition to providing design-assist services, the team provided power, lightning protection, fire alarm, and technology construction management services, and the Encore Electric service team helped install flight simulators (SIMs) in collaboration with the manufacturer.

During the project, it was necessary to install and make available two of the twelve SIM bays before the project’s completion. To meet the accelerated schedule, Encore Electric completed building Intermediate Distribution Frames (IDF) on two of the four floors before the surrounding construction otherwise would have been ready. This was done to avoid any construction activities in areas where sensitive network equipment was installed and to prevent interference with the SIMs while they were in use.

“It was quite a sequence of events”, said Tim Leuch, Encore Electric project manager. “A big challenge was the procurement of the Power Over Ethernet (PoE) network switches in time for the two-bay SIM completion. To meet the goal, we used temporary network switches and PoE injectors to turn them up to deliver the simulators (SIMs) on time.”

The United Airlines Flight Training Center is one of the first of its kind to use PoE for the lighting system control and power. PoE lights are powered by nodes throughout the facility which directly connect to category 6-rated cabling. Construction teams worked through many design challenges to understand the intricacies of the system, which created some scheduling challenges that required a high level of coordination with all trades.

The project was further complicated by the need to integrate two separate sophisticated fire alarm systems from different vendors, which were treated as a single system by the City of Denver for code enforcement. Another requirement was the City of Denver’s Green Building Code, which stated that 70% of the roof must be covered in solar. Obtaining permits through the city was a lengthy and detailed process. Typically, a project of this size and scope requires two to three permits; this project required several dozen.

Unique to this project were several requirements for how the work would be completed, including a diversity participation standard which United includes in their project goals. This meant Encore Electric partnered with teams from Minority/Women-Owned Businesses (MWBE) to meet the goal. The Encore Electric team was comprised of two experienced superintendents, technology specialists and architects, engineers, craftspeople, and prefabrication professionals who ensured all the trades met the high standards of Encore Electric, stayed on schedule, and prioritized safety at all times. This project was built by craftspeople representing all Encore Electric services, which was crucial for managing the aggressive schedule and complexity.

“A specialized and complex project like this is filled with various scheduling challenges for a 362-day-a-year secured and active campus, operating 20 hours per day”, said Jeff Morell, Encore Electric project manager. “The Encore Electric approach to managing schedule impacts varies from trade partner coordination, material acquisition, and facility outages required to tie new systems into existing systems. This approach was key to adhering to the aggressive schedule while meeting project specifications and United’s nationwide standards.”

“Seeing the project come to a close and being able to see the SIMs fully functional is really cool”, said Ken Pease, Encore Electric service technician. “Knowing the pilots come to this facility from all over the world to use these SIMs is a really big deal and it is something our team ought to be proud of.”

The work Encore Electric did on this project demonstrates integrating the company’s diverse areas of expertise, commitment to safety, and ability to overcome unique challenges. This project not only meets the customer’s immediate needs but will also contribute to the community and open opportunities for future collaborations with the general contractor, customer, and trade partners.

Remember to friend, follow and connect with Encore Electric on Twitter, Facebook and LinkedIn